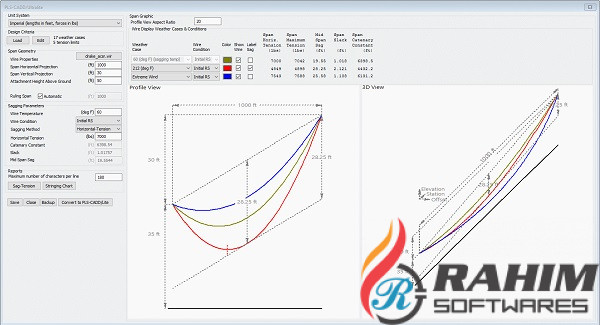

This catenary table is transformed in a Preliminary SagTension Graph, in Fig.4. b) initial tension (when installed) at 600F w/o ice or wind (“bare” cable) not to exceed 35% RBS: T

working tension) was selected less than MRCL, in order for this ADSS cable to cope with limit c) presented below. Tensions Limits: a) Maximum tension at Oo F under heavy loading not to exceed 51.35% RBS: MWT=51.35%RBS. International Wire & Cable Symposium Proceedings 1999 a In Fig.2 the designations are: S= span length half span length (assuming level supports) D= sag at mid-span H= tension at the lowest point on the catenary (horizontal tension) - only for level span case, it is in the center of the span T= tension in cable at structure (maximum tension) P= average tension in cable L/2=arc L/2=arc length of half-span I= arc length from origin to point where coordinates are (x,y) Point of the catenary curve is defined as the first derivative of the function of the curve: Which has as solution: (13) integrating rel.(13) results:Īlso,the equilibrium equations results in: =HĬonsidering rel. Additionally, the results of this work were compared and validated by common industry sag &tension software, including Sag10 and PLS-CADD.įig.1 presents an ADSS cable element under the extrinsic (wind and ice) stresses and intrinsic (cable weight) stresses, with a length, On the curve y(x), given by the Following thorough and repeated stress-strain and creep tests, this paper will show that ADSS cable has both an “initial state” and a “final state”, each state having an ‘unloaded” (bare cable) and a “loaded” (ice and/or wind) case with resulting sag 8 tension charts as a function of creep and CTE. There is also confusion between the “final state” (after creep) and the ‘loading condition” (wind+ice). However, the great majority of applications require very exact determination of sag and tension, and the influence of the above factors is important.

the presentation of data in this manner is appropriate. In some applications where the sag and tension performance of the cable is not critical. and the difference between the initial and final modulus. Stress-Strain, Creep, and Temperature Dependency of ADSS (All Dielectric Self Supporting) Cable’s Sag & Tension Calculation Cristian Militaru Alcoa Fujikura Ltd., Spartanburg, SC Abstract It has been common in the industry to calculate sag & tension charts for ADSS cables without taking into consideration the influence of creep, coefficient of thermal expansion (CTE).

0 kommentar(er)

0 kommentar(er)